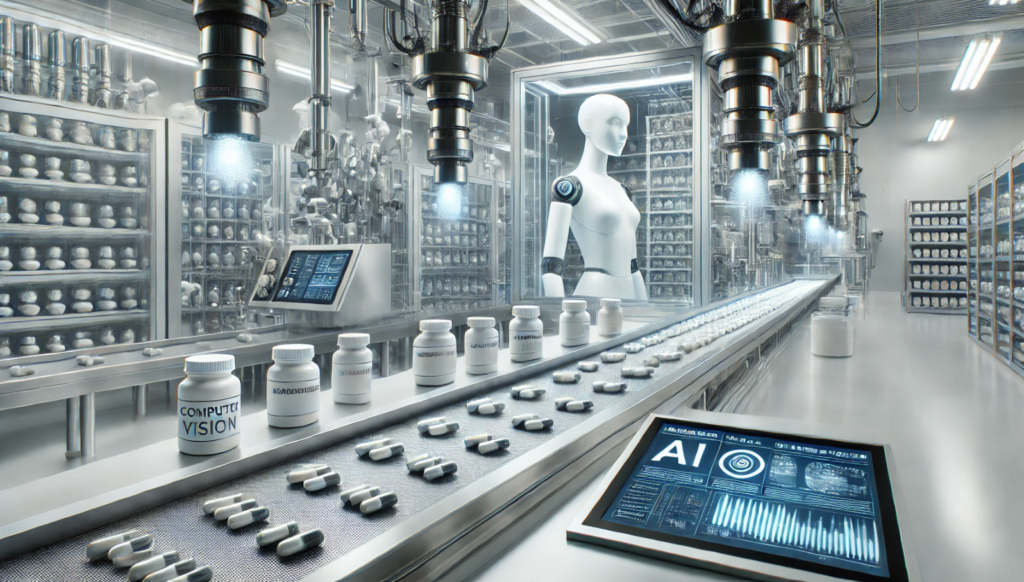

The last 40 years have achieved remarkable progress in the pharmaceutical sector, with the discovery of new drugs and modernized manufacturing processes. However, it can easily be claimed that the introduction of machine vision and AI tools would mark one of the most transformational developments in current times.

Why Pharmaceutical Companies Are Interested in AI Tools Implementation

Pharmaceutical companies are increasingly turning to AI systems and machine vision technology to enhance their operations for several compelling reasons:

Improved Inspection Efficiency: Traditional visual inspection tasks are slow and prone to human error. Machine vision systems and AI tools offer consistent and high-speed inspection of products, improving accuracy and reducing defects such as cracks in capsules and packaging.

Cost Reduction: By automating quality control and pharmaceutical production processes, companies can reduce labor costs, improve productivity, and minimize waste.

Enhanced Drug Discovery: AI in the pharmaceutical industry is being leveraged to streamline drug discovery, helping companies identify potential drug candidates faster and more accurately, which significantly shortens time-to-market.

Compliance and Regulatory Standards: Ensuring adherence to good manufacturing practices (GMP) is critical. AI-based systems help pharmaceutical manufacturers maintain compliance with Food and Drug Administration regulations by automating and improving process monitoring.

Data-Driven Decisions: AI and machine learning technologies enable the pharmaceutical industry to leverage massive datasets, enhancing decision-making capabilities in both drug product development and manufacturing.

Computer Vision Systems in Pharma Industry: A Few Examples

AI and machine vision technologies are versatile, finding applications throughout the pharma industry. Below are just a few use cases in the pharmaceutical industry that highlight how this technology is applied to various production and quality control tasks.

Computer Vision for Capsules Quality Control

Machine vision systems are widely used in pharmaceutical inspection to ensure the quality of capsules during production. These systems use computer vision platforms to detect defects such as cracks, color irregularities, and shape deviations in capsules.

A recent study published in Journal of Sensors [1] demonstrated the effectiveness of machine vision solutions in capsule inspection. The system used AI to capture high-resolution images of capsules and applied advanced image recognition algorithms to detect any inconsistencies in real-time. By automating this process, manufacturers can enhance the quality control of their capsules, ensuring that only defect-free products move forward in the production line. This leads to significant improvements in pharmaceutical production efficiency and reduces waste.

Deep Learning Algorithms for Blister Package Identification

The use of deep learning algorithms in blister packaging has transformed how pharma manufacturers identify and manage packaging processes. Blister packaging is common in the pharma industry for protecting drugs, but identifying faulty packaging can be a tedious and error-prone task without automation.

A study published by IEEE [2] outlines how deep learning models are being applied to improve blister package identification. These algorithms analyze the geometric and visual patterns of blister packs, ensuring the integrity and quality of drug packaging. AI tools can detect inconsistencies like missing tablets, incorrect sealing, or misaligned packages, helping manufacturers maintain strict quality standards. The result is a highly accurate, automated inspection process that can handle high volumes of production with minimal human intervention.

AI Tools in Drug Discovery

AI applications are not limited to production; they are also reshaping the drug discovery process. The use of machine learning methods in identifying potential drug candidates has drastically shortened research timelines and reduced the cost of pharmaceutical production.

A study published in ChemBioChem [3] discusses how AI-driven platforms are being used across various stages of drug discovery, from screening large datasets of chemical compounds to predicting their success as drug candidates. By leveraging machine learning models, researchers can expedite the drug development process, identifying the most promising compounds and optimizing other stages, like chemical synthesis and drug repurposing. This approach enhances the efficiency of pharmaceutical pipelines, helping companies bring new drugs to market faster.

Accelerating Pharmaceutical Innovations through Computer Vision

The implementation of computer vision systems in the pharma industry is leading to faster and more accurate innovations. Below are several ways machine vision technology is contributing to pharmaceutical advancements:

Real-Time Monitoring: By using computer vision platforms, pharmaceutical manufacturers can monitor production lines in real-time, ensuring that quality control is upheld throughout the process.

Better Accuracy: Computer vision and AI systems detect and address issues during the manufacturing and packaging processes, reducing the risk of defective products reaching the market.

Improved Supply Chain Management: The use of machine vision systems in supply chain operations helps companies manage pharmaceutical supply chains more efficiently, from production to distribution, ensuring high-quality products reach patients faster.

Increased Automation: Machine vision solutions automate various manual tasks, reducing the need for human intervention and minimizing errors. This improves overall production efficiency.

These are just a few of the many benefits that computer vision technologies bring to the pharma industry. The growing use of AI tools promises to revolutionize the field further.

Consult Us for AI Integration in Healthcare

If you’re ready to take advantage of AI and machine vision technologies in your healthcare or pharmaceutical business, Neural Board is here to help. Contact us today for expert advisory and integration services tailored to your specific needs.

References

- Dong, Hao, et al. “Surface quality automatic inspection for pharmaceutical capsules using deep learning.” Journal of Sensors 2022.1 (2022): 4820618.

- Han, Yun, et al. “Pharmaceutical blister package identification based on induced deep learning.” IEEE access 9 (2021): 101344-101356.

- Abbas, M. K. G., et al. “The Role of AI in Drug Discovery.” ChemBioChem 25.14 (2024): e202300816.

Q: How does automation improve the inspection process in the pharma industry?

A: Automation improves the inspection process in the pharma industry by reducing human error associated with manual inspection. Automated vision inspection systems utilize advanced vision software to ensure consistent product quality and faster throughput in pharmaceutical manufacturing.

Q: What is a vision inspection system, and how does it work?

A: A vision inspection system is an automated solution that uses camera technology and computer vision to inspect pharmaceutical products. It captures images of vials and analyzes them using machine learning algorithms to identify defects or inaccuracies in real time.

Q: How can software help companies in the pharmaceutical industry?

A: Software can help companies in the pharmaceutical industry by streamlining the inspection process, providing real-time data analysis, and improving the overall quality control of products. This leads to enhanced efficiency and reduced risk of defective products reaching the market.

Q: What advantages does using machine learning provide in pharmaceutical inspection?

A: Using machine learning in pharmaceutical inspection offers advantages such as improved defect detection, predictive analytics for maintenance of equipment, and enhanced adaptability to new inspection criteria. These benefits help optimize the inspection system for better performance.

Q: How does the concept of Pharma 4.0 relate to inspection in pharmaceutical manufacturing?

A: Pharma 4.0 relates to the digitization and automation of pharmaceutical manufacturing processes, including inspection. It emphasizes the integration of advanced technologies like AI and machine vision to enhance operational efficiency, product quality, and compliance in the pharma industry.

Q: What challenges do pharma companies face when implementing AI for inspection?

A: Pharma companies face several challenges when implementing AI for inspection, including the need for significant investment in technology, the complexity of system design, and the requirement for staff training to effectively use and manage AI-driven inspection systems.

Q: Can traditional machine vision techniques still be relevant in pharmaceutical inspection?

A: Yes, traditional machine vision techniques can still be relevant in pharmaceutical inspection, especially when combined with modern technologies. They can serve as a foundation for enhancing inspection processes while integrating new advancements in AI and machine learning.

Q: Why is product quality crucial in the pharmaceutical industry?

A: Product quality is crucial in the pharmaceutical industry because it directly impacts patient safety and efficacy. Ensuring high standards of quality through effective inspection systems helps prevent defects in pharmaceutical products, thereby protecting consumers and maintaining regulatory compliance.